ELECTRICITY ON THE layout

Current / voltage is an elementary part of the model railway layout. What conjures up light and movement can unfortunately also lead to a fire ... which then also lights up and moves, but before it is unintentional.

Therefore, there are a few things to watch out for when dealing with electricity.

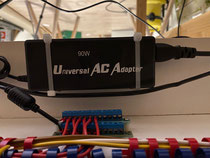

The correct power supply.

When choosing the right power supply unit, you should already know the required voltage (in volts) as well as the type of current (direct current DC, alternating current AC) and the required current (in amperes).

Most of the things on the model railroad layout require direct current. In the past, lighting was operated with alternating current. But due

to the LED technology, DC power supplies should also be used here.

What voltage is required? You can usually find out if you consult the instructions for use or the manufacturer's description.

With our Arduinos it is 5V DC. With lighting usually about 12V. Central units, boosters and decoders can demand between 14V and 30V. Depending on the gauge and headquarters, even more.

How many amps you need depends on the components you want to operate with it. You have to add the power consumption of all components that are to be supplied with the power supply.

Now it is the case that power supplies often indicate their output in watts. You can calculate this value from your two known values, volt and ampere, by simply multiplying them together.

Example: you want to operate an LED strip with 12 signals and 20 street lights with one power supply unit. All need 12V. The LED strip draws 22W. We assume 20mA per piece for signals and lights.

So 20mA x 32 = 640mA = 0.64A.

12V x 0.64A = 7.68 watts

+ 22 watts of the LED strip would be about 30 watts total power.

The cable

One could now cannibalize what a cable and what a line is. Since the electricity doesn't care about this in the first place, so is us.

Of course there are the various cables and lines on a model railway layout.

- Prefabricated data cables (USB, network, S88 ...)

- Servo cable

- Lines to the tracks

- Lines to lighting elements

- Cable for the power supply of devices

But all cables and lines are made of an electrically conductive material that is usually surrounded by a non-conductive material.

So what makes the difference: the thickness, also known as the cross-section. The cross-section is given in square millimeters and always refers to a wire. If a cable consists of several cores, the specification can be e.g. 3x1.5mm². In other words, 3 wires with a cross-section of 1.5 mm² each. The cross-section is decisive for the load-bearing capacity of the wire. This depends on so many factors that would go beyond the scope of this article. Hence perhaps a simplified table for multi-core cables.

This table describes the MAXIMUM load capacity. A buffer should therefore always be included here.

Excerpt from the current rating LAPPKabel

| cross-section | load capacity |

|

0,08 |

1A |

|

0,14 |

2A |

|

0,25 |

4A |

|

0,34 |

6A |

|

0,5 |

9A |

|

0,75 |

12A |

|

1,0 |

15A |

|

1,5 |

18A |

|

2,5 |

26A |

But even more important than the load capacity is the voltage loss in long, thin cables.

Example: 15V voltage, 5m cable length, cross section of 0.14mm² loaded with 1A. So everything within the permissible load capacity.

But the 15V only becomes 13.7V at the end of the line. With analog systems, the locomotive simply runs more slowly. But with digital, important information can be lost here.

The exact loss of line can be calculated on this Website .

You can find further performances in the NEM 604 cabels under GOODIES - standarts

Fuses

There are two reasons to install a fuse:

- Line protection

- Device protection

Wir haben oben ja erkannt das eine Ader nur mit einem maximalen Strom belastet werden darf. Dieser Leitungsschutz kann durch eine Sicherung hergestellt werden. Vor die Ader überlastet, zu heiß wird und im schlimmsten Fall brennt, löst die Sicherung aus.

Der Geräteschutz sorg dafür das ein Bauteil nicht überlastet wird. Beispielsweise unserer Arduinos sollten (je nach Typ) nicht mit mehr als etwa 500mA belastet werden. Selbst wenn wir nun eine Ader mit 1,5mm² am Vin anschließen könnte der Arduino selbst durch z.B. 10A unseres Netzteil zerstört werden. Um dem Vorzubeugen wird eine Sicherung mit 500mA in die Leitung eingesetzt.

We recognized above that a wire may only be loaded with a maximum current. This line protection can be provided by a fuse. Before the wire becomes overloaded, too hot and in the worst case burns, the fuse blows.

The device protection ensures that a component is not overloaded. For example, our Arduinos should (depending on the type) not be loaded with more than about 500mA. Even if we now connect a wire with 1.5mm² to the Vin, the Arduino itself could be destroyed by e.g. 10A of our power supply. To prevent this, a 500mA fuse is inserted into the line.

connections

There are of course a lot of possibilities to connect the cables and lines. This is clear with connectors. But what to do with "open" line ends?

This can be soldered, connected to various terminals or simply put on a plug.

Here is an example of a soldered wire.

By connecting the resistor, I had the soldering iron in my hand anyway. The whole thing is insulated with a few heat shrink tubing, this is a clean thing. Disadvantage. This is a firm connection that can only be released by cutting off. But because if the lamp is defective I have to pull the wires through the small hole anyway. I would also have to cut a plug.

Terminals: There are an infinite number of types of terminals: screw terminals, spring-cage terminals, for screwing on top-hat rails, "WAGO" terminals ....

These are mostly used when you have to connect several lines with each other. If you use some screws, you should definitely use wire end sleeves. In the case of tension spring terminals and "balance" terminals with levers, the stripped cable ends can also be clamped directly.

Important: What you should NEVER do is solder the ends and then put them in the clamp!

Of course you can also use plugs. This makes sense, especially with multi-core cables. On the left in the picture, for example, the application for a servo cable which has been extended to reach the decoder.

"Tap" ring line.

This works best with such compression connectors. One part is placed over the ring line. By pressing together, the insulation is cut and an electrical contact is established. Then you can connect the branch line to the second part and simply plug it in. Simple, clean, fast.

Important: make sure the cross-section of the coupling connector is correct, and ideally with the correct coupling tool.

order

As my mom always said: "Order is half the battle."

Those who keep things in order find it much easier to find faults or make repairs, retrofits or conversions later.

Think about a color concept for your lines.

Label everything properly. The best is always "Where does the cable come from" and "Where does the cable go".

Example: Bl12St - RM2.4

-> Line from Block12 stop area goes to feedback 2 pin 4.

I even have a color scheme for the binding spines in which the lines and cables are laid. Signals, power supply and track connections are always neatly separated.

There is also an NEM standard on the subject of color and lettering. The link to the NEM 605 system wiring can be found under GOODIES - standards

Important: You have to understand your concept and that in 10 years.

Diese Webseite wurde mit Jimdo erstellt! Jetzt kostenlos registrieren auf https://de.jimdo.com